PAINTING MY ROOF WHITE: DOES IT MAKE A DIFFERENCE?

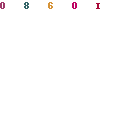

Does painting a roof white will make a difference in your cooling bill. To answer that question I used an infrared thermometer gun to compare the surface temperatures of a cedar colored asphalt shingle and another shingle on the same roof that had been painted white. These temperature readings were taken on a sunny April day in at 3 pm, (outside air temperature was 83°F). The picture below shows the results.

As you can see, the unpainted section of this roof is 173.3°F, while the section painted white is just 128.8°F. The painted shingle is 44.5°F cooler than the regular shingle. That’s a pretty significant difference in surface temperature, and I have no doubt that if the entire roof was painted white, not just two shingles, the white shingle temperature would be even lower.

Also, if the home had darker shingles, as most homes do in this area, the unpainted shingle temperature would be much higher. I’ve been on dark-gray asphalt shingle roofs in August that read over 190°F.

PAINTING YOUR ROOF WHITE WORKS, BUT…

Painting your asphalt shingle roof white can indeed make your roof surface 45-80°F cooler under the hot sun, and this should easily cut your cooling bills by 10-15%.

But there are problems with this approach, mainly finding a paint that will adhere to the asphalt shingles and last for more than a few years. In the experiment above, I used an ordinary latex paint and it’s already flaking off a few weeks later.

By comparison, the paint on metal roofing panels can last for 30 years or more.

Make sure you use a high quality paint such as

MP1 Thermal Paint

MP1 Metal Primer

MP1 Bond Primer

MP1 Metal Primer

MP1 Bond Primer

STEP 1 VISUAL INSPECTION and REPLACEMENT of DAMAGED BUILDING MATERIALS

The substrate to be coated must be in SOUND condition. Physically inspect the surface area for missing or damaged building materials. Replace and/or repair all damaged areas back to sound and solid condition.

Check for loose or missing fasteners (screws) and tighten or replace them.

Inspect for any existing leaks and be sure to repair leaks prior to the application of coating.

Make sure roof is adequately vented. Check with a roofing contractor if necessary.

STEP:2 PRESSURE CLEANING

High Pressure Blast entire roof surface with at least 1500 P.S.I. of pressure using a water and chlorine solution (approximately 1 quart chlorine to 5 gallons of water). Thoroughly remove all dirt, oil, grease, residues, mold, mildew, algae and any other surface contaminants. Severe mildew requires a stronger concentration of chlorine. When roof is completely cleaned, rinse with water only.

Let roof surface dry at least 12 hours before continuing.

All MP1 Coatings have excellent mildew resistance, but WILL NOT kill mildew already on the surface.

All MP1 Coatings have excellent mildew resistance, but WILL NOT kill mildew already on the surface.

STEP:3 RUST TREATMENT

Apply MP1 METAL-PRIME (now available in white) using brush, roller, or airless sprayer. Spot Prime all rusted areas and let dry at least 8 hours before applying the second coat of primer to the effected area(s). Consideration should be given to use two complete coats of metal primer to reduce the possibility of future rust.

Apply the primer according to label instructions covering the entire rusted surface. Let final application of primer dry at least 8 hours before continuing.

STEP:4 CAULKING SCREWS

Patch and Caulk all screws or fastener heads, cracks, crevices, fractures, holes, valleys, vents, voids, etc., with MP1 Flexi PATCH. Use a trowel or stiff brush to apply. Multiple coats are better than one thick coat if possible. The thicker Flexi PATCH is applied the longer it will take to dry. Wait at least 4 hours before applying a second coat of FLEXI PATCH and let final application dry at least 24 hours before continuing to next step. Flexi PATCH dries from top to bottom, so be careful when working around a caulked area since it will be skin dry. There is no problem coating over Flexi PATCH even if it is not completely dry, since it is a high solids material.

NOTE: FLEXI PATCH allows minimal shrinkage, but the thicker it is applied the more it will shrink. Check Flexi PATCH after 24 hours to check on shrinkage.

STEP: 5 TAPING SEAMS

Tape all visible seams, large cracks and fractures prone to water intrusion on roof surface. Apply a liberal coat of MP1 Bonding primer directly to the Tape affected area using brush, roller or airless spray and lay the MP1 TAPE directly into the WET MP1 BOND Primer .Press firmly in place and smoothout wrinkles and bubbles.

Tape must be put down before BOND PRIMER has had a chance to start drying (approximately 15 minutes).

After all areas are taped let dry for 1 to 2 hours. Apply a second light coat of MP1 BOND Primer over the top of the tape. Let the taping procedure dry for at least 2 hours before continuing

Step 6 ( If Applicable) Treat raised skylights with appropriate paint.

STE :7 PRIME COAT

Apply MP1 Bond PRIMER using 1- brush, 2- at least a one inch nap roller, or 3- at least a 1 gallon per minute, 3,000 P.S.I. piston type airless sprayer with a minimum tip size of .019 tip.

When Spraying or Rolling MP1 BOND Primer , it must be applied perpendicular to the slope of the roof; example: If the slope of the roof runs from North to South then the coating will be applied from East to West. This will be the start of a checkerboard application pattern.

Apply the MP1 BOND PRIMER at a rate of 200-250 square feet per gallon covering the entire roof surface. Let MP1 BOND PRIMER dry at least 12 hours before continuing.

STEP: 8 FIRST COAT of FINISH/TOP COAT

Be sure entire surface is clean and free of all moisture. Be sure the entire area to be coated is primed, if not, then spot prime as needed.

Apply MP1 Thermal Roof Coating using 1- brush, 2- at least a one inch nap roller, or 3- at least a 1 gallon per minute, 3,000 P.S.I. piston type airless sprayer with a minimum tip size of .027 tip, ( note larger size tip is needed ). Remove tip and gun filters before starting.

When Spraying or Rolling MP1 Thermal Paint, the first coat must be applied perpendicular to the coat of MP1 BOND Primer to achieve a checkerboard pattern.

Apply the first coat of MP1 Thermal Paint at a rate of 100-125 square feet per gallon per coat over the entire roof surface. Wet film thickness of 12-15 mils resulting in dry film thickness of 8-10 mils. Let dry at least 12 hours before continuing.

STEP#: 9 SECOND COAT of FINISH/TOP COAT

Be sure entire surface is clean and free of all moisture. Be sure the entire roof area is completely coated, if not, then spot coat.

Apply MP1 Thermal Paint using 1- brush, 2- at least a one inch nap roller, or 3- at least a 1 gallon per minute, 3,000 P.S.I. piston type airless sprayer with a minimum tip size of .027 tip. Remove tip and gun filters before starting.

When Spraying or Rolling MP1 Thermal Paint , the second coat of MP1 Thermal Paint must be applied perpendicular to the first coat of MP1 Thermal Paint completing the checkerboard pattern.

Apply the second coat of MP1 ThERMAL paint at a rate of 100-125 square feet per gallon per coat over the entire roof surface. Wet film thickness of 12-15 mils resulting in dry film thickness of 8-10 mils. Let dry at least 24 hours before your Final Evaluation.

STEP#: 10 FINAL EVALUATION FOR MP1 CERTIFICATE

At this time a detailed evaluation of the completed job will determine the quality of the workmanship and whether strict application specifications have been met. The entire roof surface must be completely coated & sealed. Be sure to check that all roof areas are completely coated and sealed under permanently placed roof items such as roof top air conditioning units.

Divide roof into 1,000 square feet sections and randomly check one spot in each section for a dry film thickness of at least 20 mils. Remember to touch up the penetration made by the dry film thickness gauge. If specifications have not been met, determine how much material will be required to meet specifications and recoat. Check dry film thickness again until specifications have been met.

Thanks for the explanation!

ReplyDeleteYou can use Elcometer 500 to measure coating thickness